Investigation of Practical Electro-catalysis using the Floating Electrode

Find Similar History 12 Claim Ownership Request Data Change Add FavouriteTitle

CoPED ID

Status

Value

Start Date

End Date

Description

The purpose of this project is to investigate the behaviour of electro-catalysts at the high current densities they need to operate at for industrial electro-catalysis applications. The main context of the project will be the cathode catalyst layer responsible for the oxygen reduction reaction (ORR) in PEM fuel cells. The ORR is the most difficult reaction in a PEM fuel cell and improvements to this reaction rate are the main route to lower cost membrane electrode assemblies (MEAs), because the currently required PGM loading on the MEA cathode is considered too high. Lower cost MEAs will enable wider penetration of fuel cells into existing and developing markets, such as automotive.

At present, only one electrochemical method is available that can probe electro-catalysis behaviour of gas diffusion electrodes outside of an MEA at high current density; this is the Floating Electrode (FE) method developed at Imperial College in Prof. Kucernak's group . The principle of the FE is shown in Figure 1: the electro-catalyst is simultaneously in contact with gaseous reactant, aqueous electrolyte and a good electronic conductor (sputtered gold). A key feature of the technique is its ability to bridge the gap between studying discrete electro-catalyst agglomerates and continuous catalyst layers of different PGM loading, whilst avoiding the complicating issues encountered using full-blown in-cell MEA testing. Whilst the feasibility and utility of this method has been shown by Chris Zalitis and bought in-house to JMTC, application of the FE has thrown up many new questions, for example:

1. Why does the mass activity of the ORR catalyst (Pt/C) apparently decrease significantly with increased electrode loading?

2. How limiting to the ORR is the proton conduction within the catalyst layer and within the electrolyte that the catalyst layer contacts (solid membrane or aqueous acid)?

3. Can it be definitively shown that Pt alloy catalysts are actually less active at high current densities than Pt-only catalysts, despite the converse being true at low current

densities?

Resolution of these questions will feed in to the FCR group understanding of the behaviour of MEAs and complimentary work will focus on applying the understanding to improved catalyst and catalyst layer design.

Once the fundamental questions above have been resolved, the project in its later stages can examine other gas-phase electro-catalyst systems. These will include the hydrogen evolution reaction, ubiquitous at the cathodes of industrial electrochemical processes such as electro-chlorination and central to the generation of hydrogen from renewable energy using PEM electrolysers. Further, the flexibility of electrochemical systems enables the use of intermittent renewable energy to synthesise valuable chemicals other than hydrogen, including ammonia and small chain hydrocarbons. The FE allows such high rate gas-consuming or gas evolving electrochemical reactions to be studied in a fundamental way under much more realistic conditions.

| Imperial College London | LEAD_ORG |

| Johnson Matthey (United Kingdom) | STUDENT_PP_ORG |

| Anthony Kucernak | SUPER_PER |

Subjects by relevance

- Hydrogen

- Fuel cells

- Catalysis

- Electrochemistry

- Catalysts

- Electrolytes

- Reactions

- Electrolysis

Extracted key phrases

- Cathode catalyst layer responsible

- Continuous catalyst layer

- Catalyst layer design

- ORR catalyst

- Pt alloy catalyst

- Catalyst system

- High current density

- Investigation

- Catalyst agglomerate

- Practical Electro

- Catalysis behaviour

- High rate gas

- Catalysis application

- Industrial electro

- Pem fuel cell

Related Pages

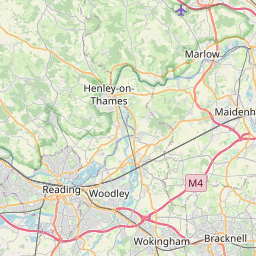

UK Project Locations