A multi-scale, high-resolution, tri-beam facility for fast machining and 3D characterisation

Find Similar History 28 Claim Ownership Request Data Change Add FavouriteTitle

CoPED ID

Status

Value

Start Date

End Date

Description

The performance and applications of advanced materials, such as aeroengine turbine blade materials, which need to operate at very high temperatures to achieve high efficiency; new energy materials such as thermal energy storage materials, lithium ion battery materials and next generation battery materials; and healthcare materials, are largely controlled by their microstructures which cover a wide range of length scales from nanometres to millimetres. To exploit existing materials and to develop new materials requires high resolution (so that very fine details can be identified), multi-scale characterisation of the microstructures (so that heterogeneous structure can be revealed) in three dimensions (3D). Developing our capability in materials characterisation is one of the most important areas for materials science and engineering.

There are a range of existing 3D materials characterisation techniques including atom probe tomography, transmission electron tomography, FIB slicing and view, X-ray tomography. However there is a noticeable gap, from about 100 um to 1 mm, where current existing techniques are not able to characterise within a practical time frame. This proposal is to develop a unique multi-scale, high-resolution, tri-beam facility for fast machining and 3D characterisation. This new facility will have a femto-second laser beam, a multi-species plasma beam and a high-resolution electron beam. The femto-second laser is able to machine materials 15000 times faster than a conventional FIB. The multi-species ion plasma beam will enable the machining of a wide diversity of materials including materials for healthcare technology applications, energy materials and also aerospace materials. Alongside other detectors, the electron beam will enable high-resolution analysis of the materials prepared by the laser and plasma beams. Therefore the new facility will enable the characterisation of the chemistry, crystallography, morphology and other functional properties of materials from 100 um to 1 mm currently challenging for other characterisation techniques. The integration of a glovebox will facilitate the handling and characterisation of air-sensitive materials including battery materials. Importantly, the inert transfer device will allow transfer of materials from this instrument to other characterisation facilities such as transmission electron microscope where even higher resolution analysis can be performed.

This instrument will revolutionise the materials characterisation capability and capacity in the UK leading to accelerated advanced materials and manufacturing development in many important fields including battery materials, aerospace material, energy storage, 3D printing and bio-medical materials.

More Information

Potential Impact:

The multi-scale, high-resolution, tri-beam facility will benefit a wide range of disciplines: Chemistry, Materials Science, Chemical Engineering, Manufacturing, Medicine and Dentistry. The new instrument will facilitate on-going research programmes ranging from nanoparticle imaging, new healthcare technology materials development, developing new energy storage materials and next generation battery materials, new aeroengine materials and the manufacturing of a range of functional materials such as fabrication of sensors for DSTL applications and functional gradient additive manufacturing. The proposed equipment will therefore impact a wide cross-section of the UK economy. In addition, the new facility will lead to impact across a wide range of challenges in advanced materials and manufacturing in many industry sectors. Via the strong collaborations with industrial partners, the expert investigator team will ensure maximum impact upon the UK economy is achieved in a timely manner.

The University of Birmingham, and in particular the Centre for Electron Microscopy (CEM), has well established networks supporting the research and development of regional industries. The Birmingham Research Park (BRP) offers the university a window through which to collaborate with external commercial companies and will be fully utilised to build upon these existing networks. A dedicated team is on-hand to support and manage collaborations with industrial partners, knowledge exchange programs and other commercialisation activities. The investigator team and the CEM will work closely with the BRP to ensure collaborations run smoothly and that research outcomes are maximised.

| University of Birmingham | LEAD_ORG |

| Echion Technologies | COLLAB_ORG |

| Oxford Instruments (United Kingdom) | PP_ORG |

| Thermo Fisher Scientific (United Kingdom) | PP_ORG |

| Yu-Lung Chiu | PI_PER |

| Liam Grover | COI_PER |

| Phoebe Allan | COI_PER |

| Yulong Ding | COI_PER |

| Peter Slater | COI_PER |

| Moataz Attallah | COI_PER |

| Paul Bowen | COI_PER |

| Emma Kendrick | COI_PER |

| Gerard Fernando | COI_PER |

| Hanshan Dong | COI_PER |

| Damien Walmsley | COI_PER |

| Alessandro Mottura | COI_PER |

| Ian Jones | COI_PER |

| Biao Cai | COI_PER |

| Jon Binner | COI_PER |

Subjects by relevance

- Materials (matter)

- Materials science

- Microscopy

- Composites

- Electron microscopy

- Energy efficiency

Extracted key phrases

- 3d material characterisation technique

- New energy storage material

- New healthcare technology material development

- New energy material

- Material characterisation capability

- New aeroengine material

- Thermal energy storage material

- New material

- Lithium ion battery material

- Generation battery material

- Aeroengine turbine blade material

- Advanced material

- Healthcare material

- Functional material

- Aerospace material

Related Pages

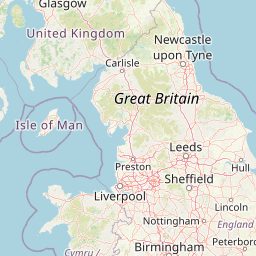

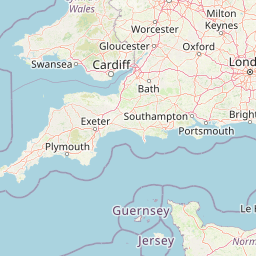

UK Project Locations