Surface Engineering Solid State Dye-Sensitized Solar Cells

Find Similar History 14 Claim Ownership Request Data Change Add FavouriteTitle

CoPED ID

Status

Value

Start Date

End Date

Description

Dye-sensitized solar cells (DSC) can be described as a form of "artificial photosynthesis" because, in both cases, light is harvested by a pigment (chlorophyll in photosynthesis or a synthetic dye in DSC). This is interesting because photosynthesis is ~5% efficient in terms of the incident light energy (i.e. photons) captured to the energy in the photosynthetic by-products. Despite this apparently low efficiency, photosynthesis has supported the planet's biosphere for aeons. One reason for this is the huge amount of sunlight which reaches the Earth's surface every day. This has been estimated to be ~6,000x more than annual global energy consumption despite the growing global population using huge amounts of energy. Given that the sun will last for billions more years, sunlight is vastly more abundant than any other energy source currently available. In this context, if we use 10% efficient PV, using only 0.2% of the Earth's surface would meet energy demands whilst releasing only trace greenhouse gases during production and none during operation. This will slow the accelerating pace of fossil fuel related climate change.

Whilst PV uptake has increased hugely recently (~11GW in UK and >225GW globally), this still represents a tiny fraction of current energy demand; the question is why? Crystalline Si PV currently dominates the market (~90%) but is heavy, rigid and is usually made from batch-like processes into limited product forms (rectangular, encapsulated, glass panels). And despite these products being available for many years, they are still bolted onto frames attached onto existing roofs with wires often running across open roof-space. They do not fit, they are a "bolt-on" solution.

This research will develop PV which can be printed by continuous (roll-to-roll, R2R) processing. Because R2R is faster than batch processing, it will reduce manufacturing costs but increase the amount of product which can be made. R2R product can also be made to any length or width which will revolutionise PV product form. Perhaps most importantly, by varying the PV substrate, this will enable PV to be fully integrated into roof/wall panels or windows. This will drastically reduce installation and balance of systems costs (i.e. PV panel mounting system, DC/AC power inverters, wiring, switches, battery storage) which make up almost half of the cost of most PV installations.

DSC technology is already in commercial production (www.gcell.co.uk) and is already known to be suitable for R2R processing. In addition, DSC raw materials are non-toxic and abundant. Whilst DSC device lifetimes >25,000h have been reported (equivalent to ~25y operation), the liquid electrolytes used can leak and are corrosive to some metals which increases substrate costs. This proposal will exchange this liquid electrolyte for a solid, charge carrier to make solid state DSC (ssDSC) devices to avoid these issues.

Whilst ssDSC have been made before, it has been difficult to control their construction because this involves depositing 2 thin layers of different chemicals onto porous metal oxide particles in a porous film. The resulting inconsistent layer coverage causes energy losses which limits device efficiency. To overcome this, we will use self-assembling molecules and computer modelling to explore surface chemistry/structure to speed-up the research. Thus, we will design dyes and charge carriers to behave like "self-parking cars in a car park" and move to the correct position before fixing themselves in place. Then, by controlling the self-assembly process, we will add multiple dyes into the device to increase light harvesting to improve device efficiency to reduce pay-back times; i.e. the time when the customer has saved enough money on their energy bills to pay off the system purchase costs. By combining computer modelling and experiment, we will cut design to manufacture times up to 10-fold by reducing the number of material modification cycles required.

More Information

Potential Impact:

1. The proposal will deliver a step-change in solid state DSC (ssDSC) efficiency and lifetime using scalable technology which is compatible with roll-to-roll manufacturing to enable the potential for large scale ssDSC module manufacturing.

2. The research will develop generic methods to self-assemble bespoke electronic materials at interfaces by solution processing which will be widely applicable to other advanced devices (e.g. sensors, disease control, catalysis).

3. The proposal will provide a case study of iterative research between theoretical scientists, synthetic chemists, materials scientists and engineers which covers the technology development pipeline from TRL1 (concept) to TRL7 (operational testing of scaled prototype).

4. Using accelerated weathering protocols to compress the duration of PV testing, the research will expand our understanding of device failure mechanisms and improve device lifetime mitigation strategies. The aim is to extend ssDSC performance under indoor exposure (target is Power Conversion Efficiency, PCE >80% of initial value after 5y) or outdoor exposure (target is PCE > 80% of initial value after 20y).

5. The research will generate high impact journal publications (e.g. Nature, Advanced Materials, Energy and Environmental Science) and be presented at international conferences (e.g. MRS, ACS, EU-PVSEC).

6. The project will generate highly trained and inter-disciplinary scientists and engineers to support the growing PV and advanced materials industry.

7. By developing a new PV manufacturing technology in the UK, the research will generate significant wealth and create jobs. For example, the European PV Industry Association has estimated that PV manufacturing creates 3-7 direct jobs in production and 12 to 20 indirect jobs per MWp.

8. The proposal will help deliver UK Govt. targets to reduce greenhouse gas emissions to < 80% of the 1990 value by 2050 including work on building integrated PV (BIPV) to help deliver DECC policy of "buildings as powers stations".

9. By developing scaled renewable energy technology to reduce fossil fuel usage and greenhouse gas emissions, the proposed research will improve global health and quality of life by addressing climate change.

10. The impact of the project will be disseminated to a wider society through public events such as STFC Daresbury Open Days (see e.g. from July 2016 http://www.stfc.ac.uk/public-engagement/see-the-science/daresbury-open-week/chemistry-workshop-solar-cell-results/) and the Swansea-led Materials Live project to coordinate impact activities from schools engagement to the production of lab demonstrator systems for public showcase.

11. The proposal will generate intellectual property (IP) and the Project Management Team will manage the exploitation of this IP through project partners, SPECIFIC IKC partners and/or new spin-out companies.

| Swansea University | LEAD_ORG |

| G24 Power (United Kingdom) | PP_ORG |

| Pilkington (United Kingdom) | PP_ORG |

| BIPVco (United Kingdom) | PP_ORG |

| Peter James Holliman | PI_PER |

Subjects by relevance

- Climate changes

- Dye-sensitized solar cells

- Energy efficiency

- Greenhouse gases

- Synthetic dyes

- Dyeing

- Energy consumption (energy technology)

Extracted key phrases

- Surface Engineering Solid State Dye

- Sensitized Solar Cells

- Synthetic dye

- PV product form

- Multiple dye

- New PV manufacturing technology

- DSC device lifetime

- DSC raw material

- Solid state DSC

- Solar cell

- DSC technology

- Incident light energy

- Renewable energy technology

- Annual global energy consumption

- PV panel

Related Pages

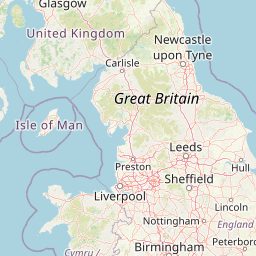

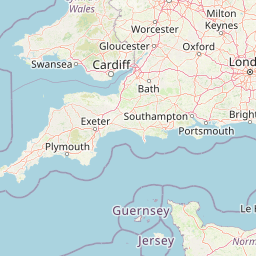

UK Project Locations